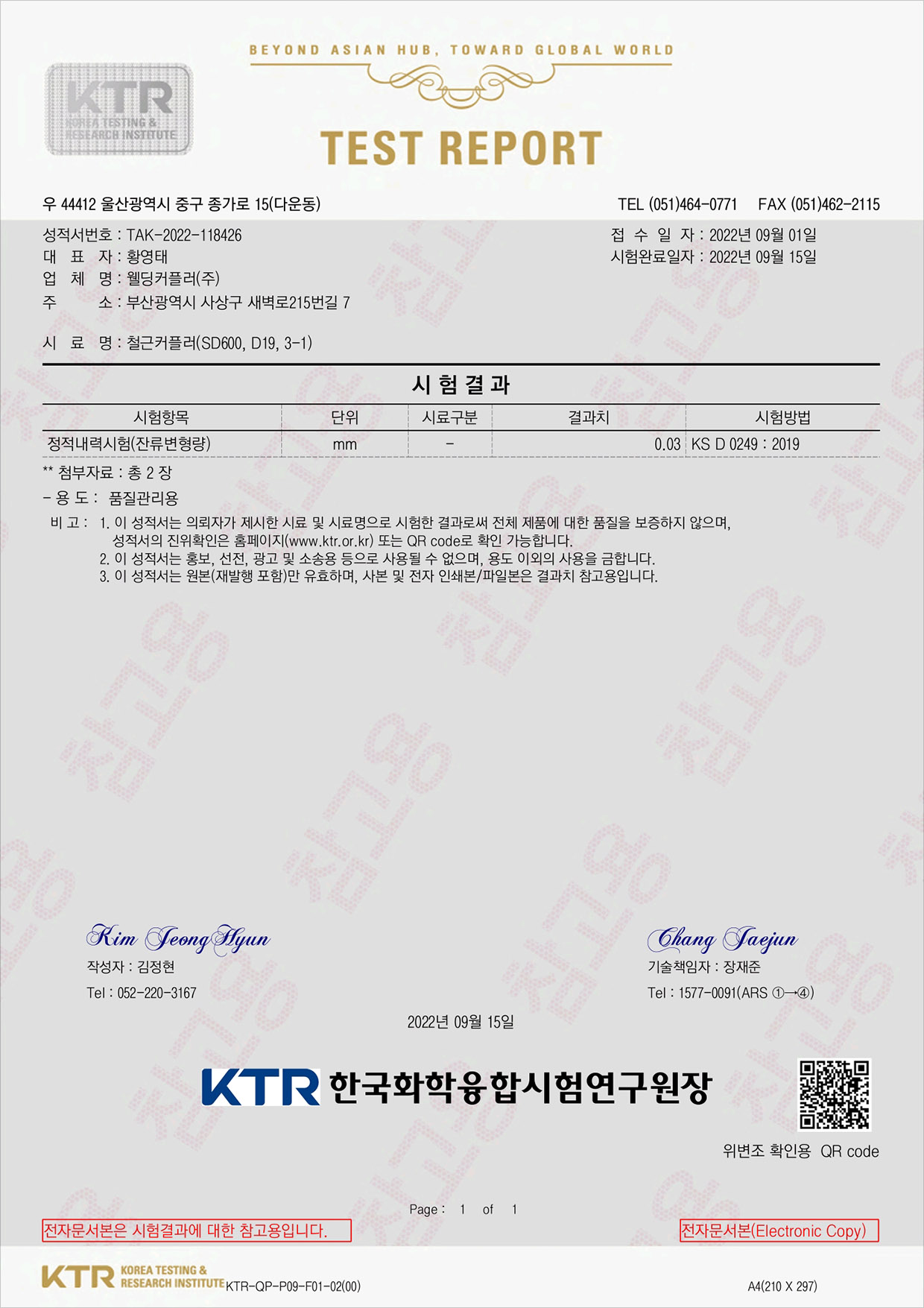

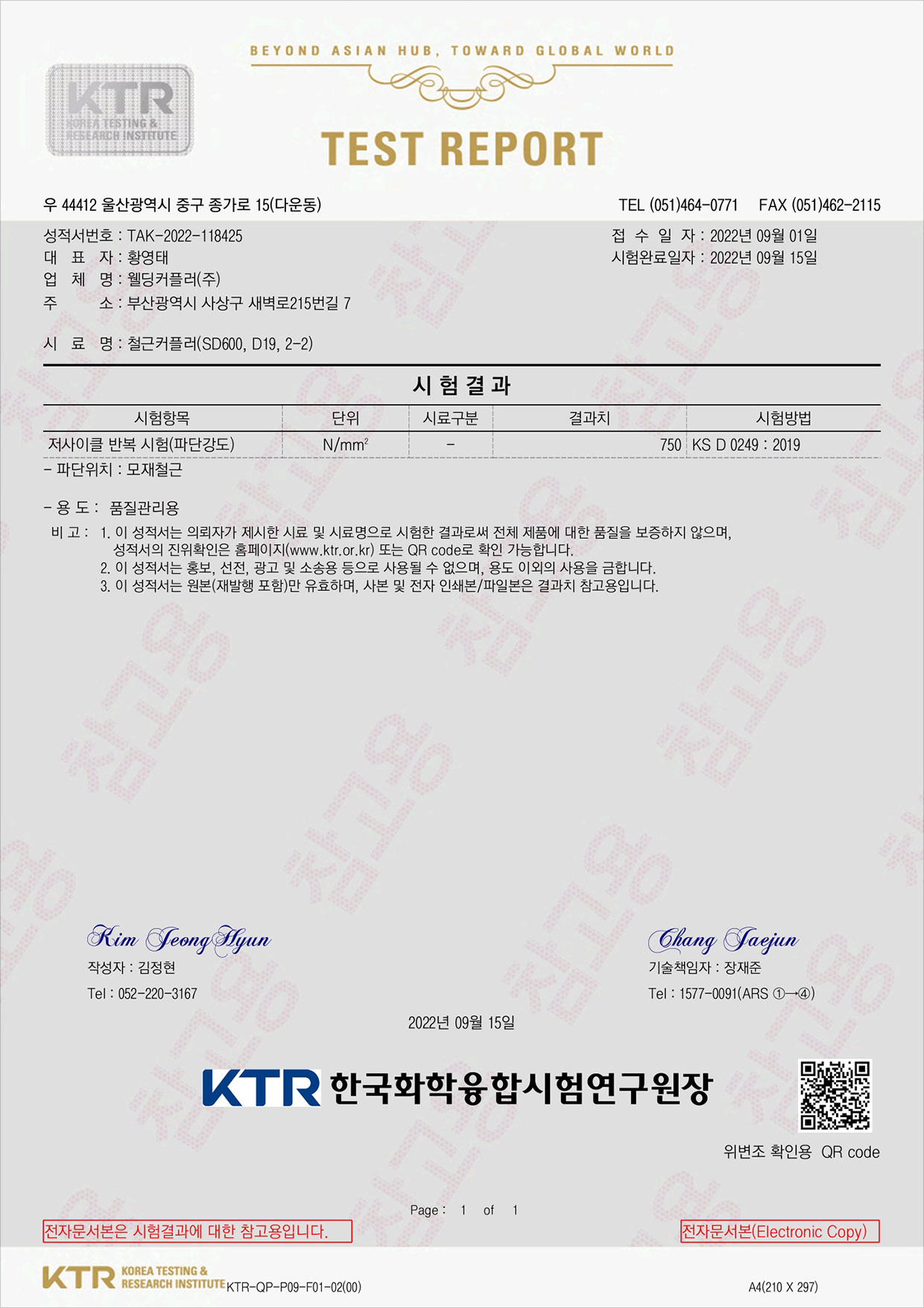

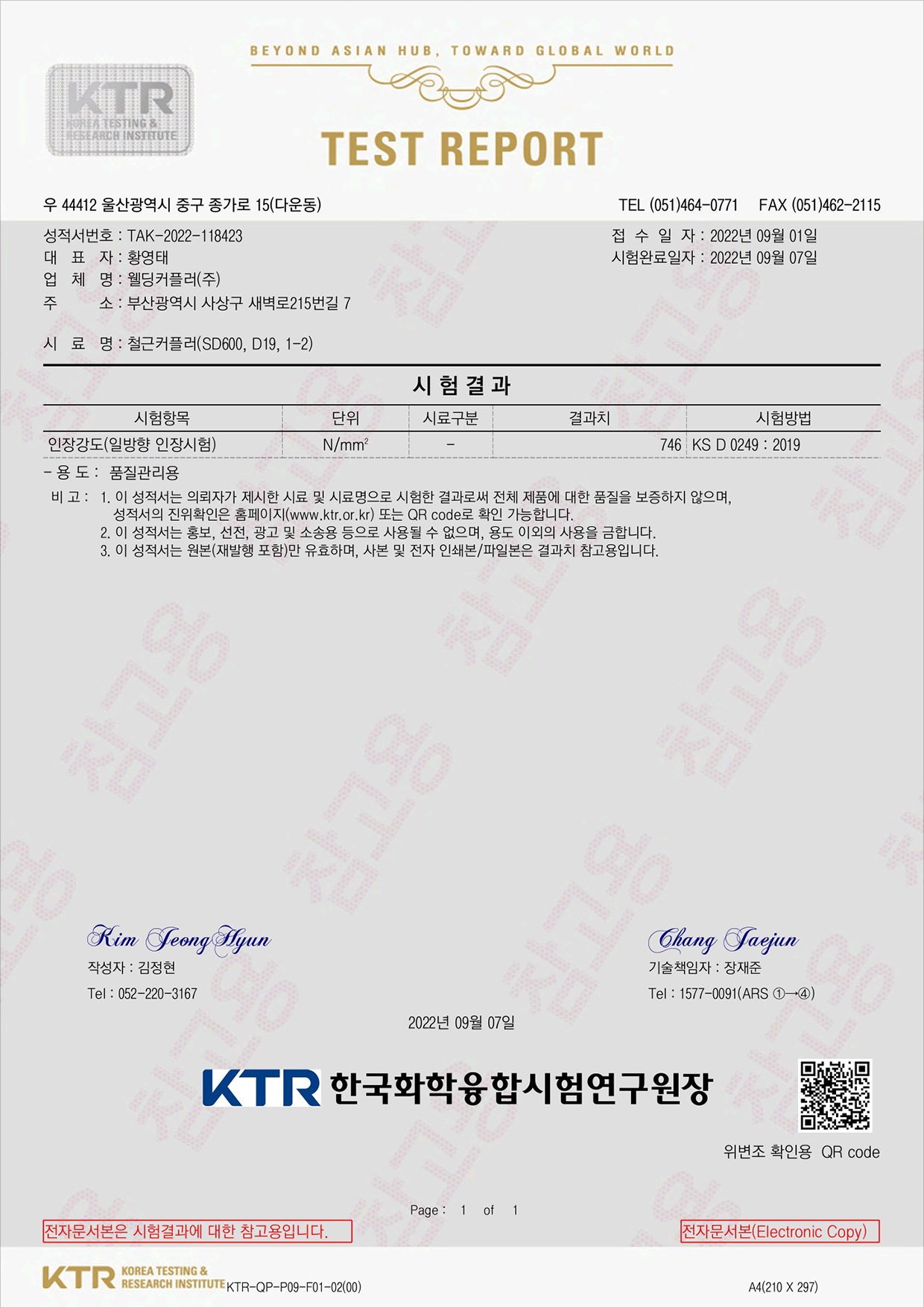

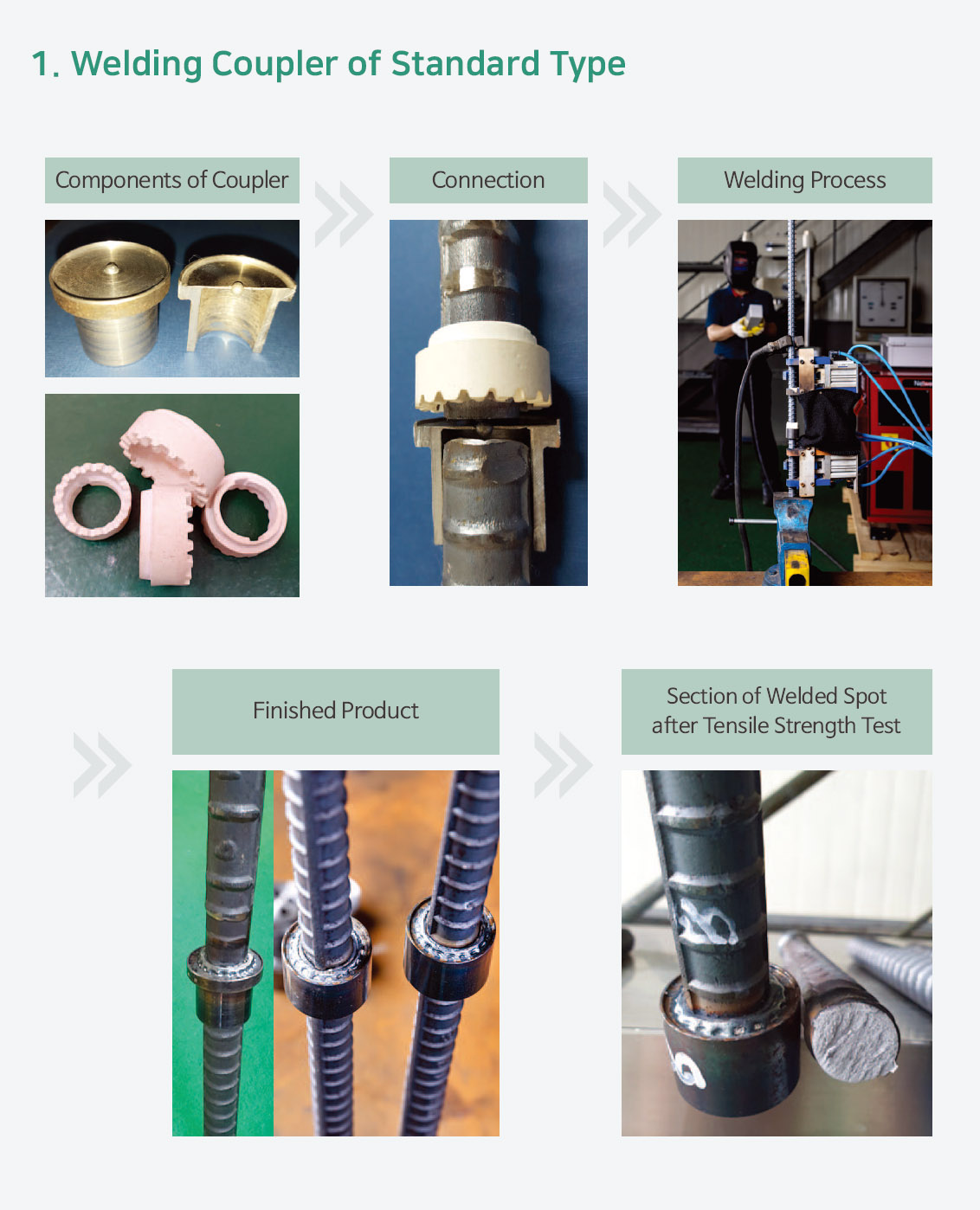

We tested performance of the welding coupler that is briefly described in the previous page. The test material was SD600 rebar. However, the Ministry of Land, Infrastructure& Transport or the Construction Association of Korea notes that rebar in the category of SD600 or higher is not suitable to be bonded by welding. According to them, SD600 rebar contains over 0.3% carbon for the purpose of strength improvement, and that ingredient reacts with O₂ in the atmosphere, resultantly forming a great deal of CO₂ bubbles.

In a situation that shaking by earthquake or other external force takes place, by the way, the CO₂bubbles put out triaxial tensile force that may cause the breakdown of rebar. This is why there’s regulations on bonding by welding rebar which has a substantial amount of carbon in content in order to improve strength. This company’s welding coupler performs melting and bonding rebar at 1800A and for less than 1 second. This way ensures nearly ‘zero’ formation of bubbles like shown in a relevant image as above. Meanwhile, the melting and bonding process decreases the tensile strength of SD600 rebar from 780~840N/mm2(Newton) by 50~ 80N/mm2 to 720~760N/mm2 because the process is naturally followed by annealing, that is, post-welding slow cooling. In order to increase its strength, generally, SD600 rebar should go through rolling at 850~880℃ and then quenching by water cooling at 680~740℃.

Anyway, tensile strength decrease as mentioned above can be solved by structural design involving rebar addition only if the material has no bubble-related defect. The most important thing is to ensure earthquake-proofness, which needs satisfying the condition of residual distortion, that is, tensile slip of 0.3mm or below, according to ICE-ES Regulations. The satisfaction means, in other words, that initial tensile slip is found ‘zero’ as a result of low-frequency or tensile strength test. That result is achievable only by the welding coupler.

|

Welding Coupler

Welding Coupler Tensile strength of seismic performance

Tensile strength of seismic performance 2 Types

2 Types

Test Report

Test Report