|

|

|

Wet Exhaust-Gas Treatment System for Odor and Dust Removal Wet Exhaust-Gas Treatment System for Odor and Dust Removal |

|

This system is a new technology-based equipment that maximizes the rate of dust collection. The equipment functions in a way that it collects all kinds of contamination sources or contamination gases which exhaust into the atmosphere. And then, the wet treatment system makes the collected gasses pass through vortex inside the water column. As a result, only clean air is discharged out. Meanwhile, contamination gases include hydrochloric acid fumes from steel wires processing, oil mist from mechanical processing, fine dust from foundries, and minute particles of dust, sulfur or nitrogen oxide from steel mills, steel works or thermal power generation plants. |

| Applications |

|

As described above, the wet exhaust-gas treatment system can deal with all kinds of contamination gases. Other options that are available to the system include settling fine dust by deposition, removing oil with the oil separator, and eliminating odor through the activated carbon layer. |

Wet Dust Collector demonstration video Wet Dust Collector demonstration video |

| [ Wet Dust Collector demonstration video ] |

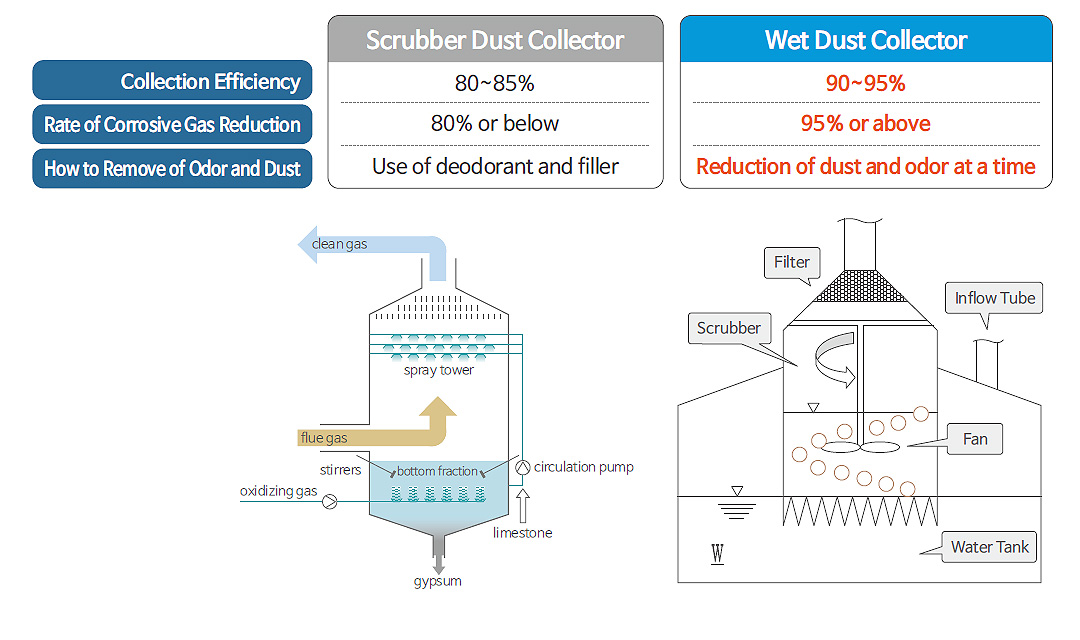

| Comparison and Discrimination from Conventional Technology | ||

|

||

| [ Problems ] | ||

|

• Due to the low collection efficiency of 70~75%, the plant where the scrubber dust collector and neighboring plants sustain oxidization. • The scrubber dust collector is structured to have a cylinder with diameter of 2500~3000mm. Inside the cylinder, there are 2 layers of demister below which plastic pallrings are placed. Dust collection is carried out in a way of spraying water onto the pallrings through nozzles. • If the concentration of hydrochloric acid increases under the operation of the collector, the substance is neutralized with sodium hydroxide(NaOH), when salt(NaCl) is formed. The salt clogs the nozzles. In this situation, hydrochloricacid fumes are intactly charged out, and oxidizes the project in which the scrubber dust collector is installed. • The plastic pallrings are placed not evenly, but one-sided. This is why hydrochloric acid fumes are intactly discharged out when being blown by the wind-power fan from the bottom of the scrubber, consequently oxidizing the plant where the scrubber dust collector is installed. • For such reason as foresaid, wire-rod processing businesses, which are usually large-sized, often have the issue of cooper wire oxidization. With oxidized cooper wires, it's impossible to connect and use solar modules for power generation that could be tremendously cost-effective. * For your information, solar modules on the rooftop create an annual revenue of KRW 3 million per about 826㎡. The modules cost KRW 120million per about 826㎡ |

||

|

|

||

|

• The former dust collector is a structure of plastic(FRP) cylinder form with the diameter of 2500~3000Φ and height of 5~6m(10M or over if 4 to 5m-high chimney is added). Inside the structure, there are 2 layers of demister and a layer of plastic pallrings. Dust collection is made in a way of spraying water over the pallring layer and then making contamination gases pass through that layer. |

||

|

||

|

• Maximizing collection efficiency by making contamination gases passes through the water column. In more detail, the gas passes through approx. 20-degree sharp-angle blades inside that column, which breaks bubbles into minute pieces. • Possible to choose among low(300mm), middle(500mm) and high(700mm) dust collection by controlling the level of water column and adjusting the drainage valve based on the analysis of contamination sources or exhaust gases. • The rotational stirring prevents bubbles of contamination gas into small pieces from rising in a vertical direction and then discharging out of the dust collection tank in a short time. The stirring process by our wet dust collector improves collection efficiency by breaking into small pieces those bubbles, delaying the time of bubble rising, and lengthening the time of dust collection. • Collecting dust in the state of negative pressure. With a suction fan in the back which functions in the state of negative pressure, our wet dust collector is workable for more than 15 years. In contrast, conventional scrubber dust collectors each with a similar fan that costs KRW 6~19 million are merely 5years in lifespan. • Possible to place options such as activated carbon layer between the wet dust collector and the suction fan depending on the source of contamination. A good example of the options is suction filter that can remove odorous contamination gases that generate when coating enamel wires, uncovering electric wires or the likes. |

||

|

||

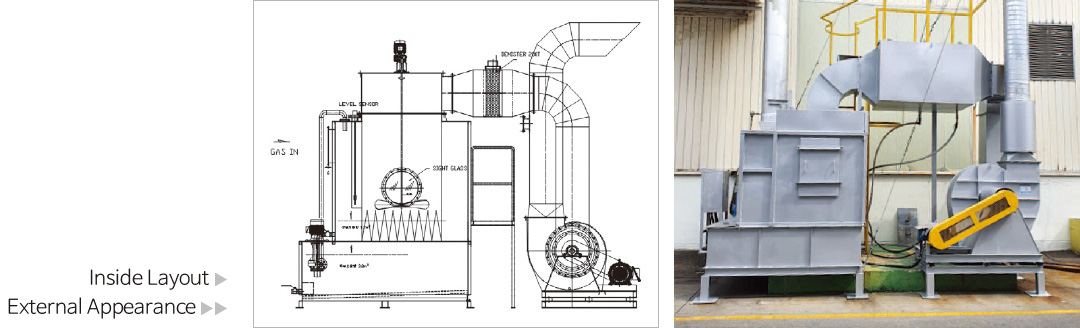

Entire Structure of West Dust Collector Entire Structure of West Dust Collector |

||

|

As shown in the layout below, the west dust collector is comprised of the upper tank, dust collection tank and the lower tank. More specifically, the upper tank has the dust collection tank inside. The dust collection tank has blades in the bottom. And, the lower tank has the settling tank inside. Here, the settling tank is mainly used to deposit fine dust particles whose settlement fails due to vortexes in the upper tank. That tank accumulates those particles by constant circulation. Besides, the wet dust collector can remove oil mist, which often generates from mechanical processing, by floating up the mist and then displacing it by using the oil separator. |

||

|

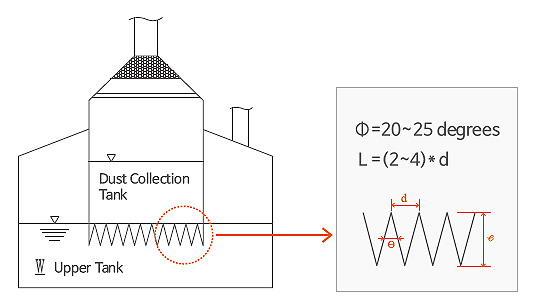

Blades in the Bottom of Dust Collection Tank Blades in the Bottom of Dust Collection Tank |

|

• Increasing the rate of dust collection by generating minute bubbles even at low pressure • Forming those bubbles which in turn create vortexes inside the dust collection tank |

|

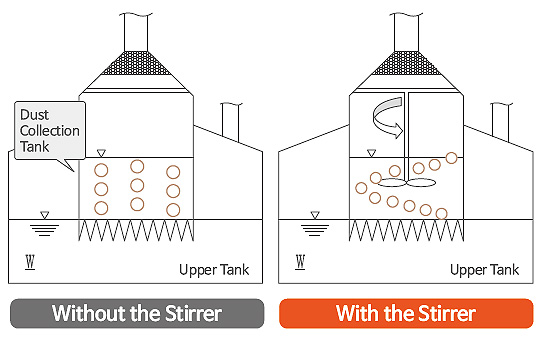

Stirrer inside Dust Collection Tank Stirrer inside Dust Collection Tank |

|

• After passing through the blades, bubbles of contamination gas are rotated by the stirrer instead of rising vertically into the water column. This extends the time of dust collection, resultantly increasing the rate of the collection. • The rotation of the stirrer allows to break large bubbles into small pieces that are then mixed, contributing to improving the rate of dust collection |

|

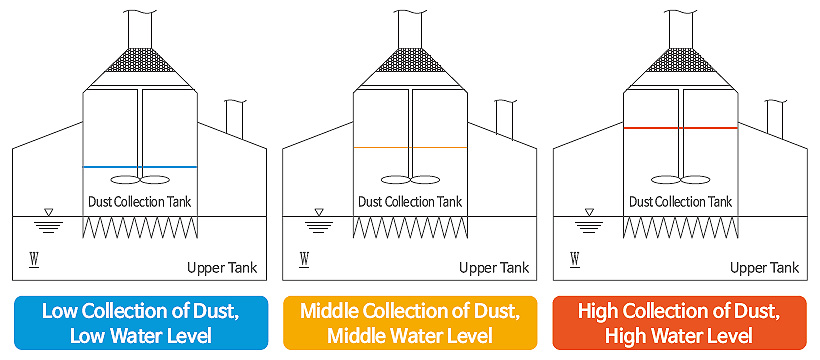

Water Level Adjustment of Dust Collection Tank Water Level Adjustment of Dust Collection Tank |

|

• Possible to control the level of water column in the dust collection tank only by adjusting drainage value of the upper tank under the condition that a certain amount of water keeps being pumped into the dust collection tank. • This adjustability of water level allows to freely choose among low, middle and high dust collection while considering collection efficiency. |

|